Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Unlocking Efficiency and Cost-Effectiveness: Exploring Sheet Metal Laser Cutting Machine Prices

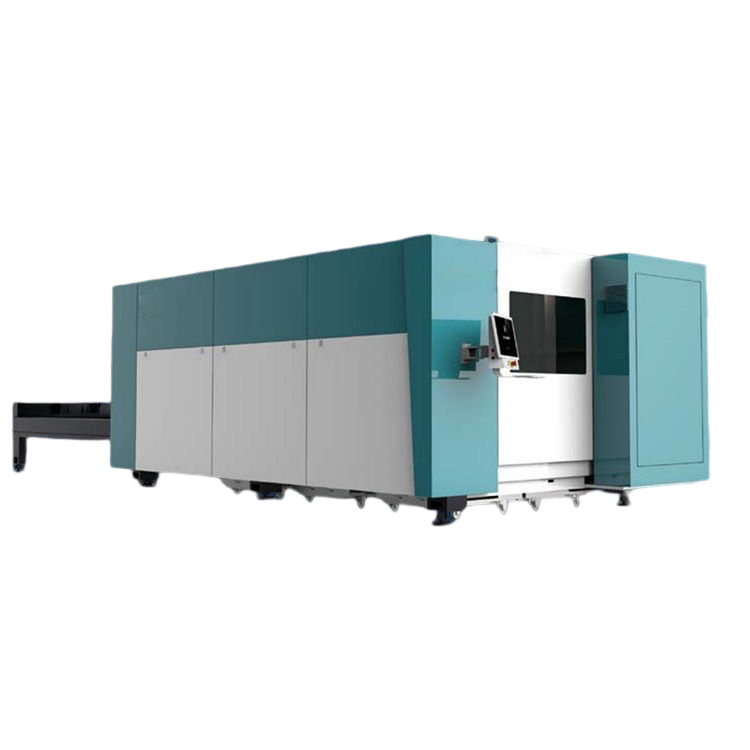

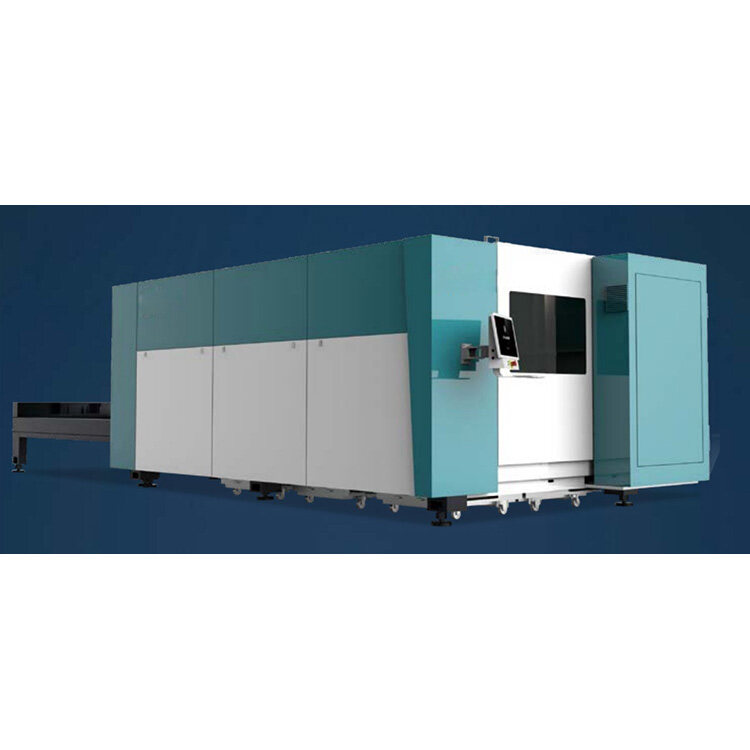

In the realm of metal fabrication, precision and cost-effectiveness are paramount. As industries evolve and demand grows, businesses are constantly seeking innovative solutions to optimize their manufacturing processes. One such solution that has gained significant traction is the sheet metal laser cutting machine. In this comprehensive guide, we will delve into the intricacies of sheet metal laser cutting machine prices, exploring factors that influence costs and strategies for maximizing value.

Understanding Sheet Metal Laser Cutting Machines

Before delving into pricing considerations, let's first understand what sheet metal laser cutting machines entail. These machines utilize high-powered lasers to precisely cut through sheet metal with remarkable accuracy and efficiency. By harnessing the power of focused light energy, they can create intricate designs and shapes with minimal material waste.

Factors Influencing Sheet Metal Laser Cutting Machine Prices

1. Machine Size and Capacity: One of the primary factors influencing the price of a sheet metal laser cutting machine is its size and capacity. Larger machines capable of handling thicker sheets and higher volumes of material command higher prices due to their increased capabilities and robust construction. Conversely, smaller machines designed for light-duty applications may be more budget-friendly but offer limited cutting capacity.

2. Laser Source and Power: The type of laser source and its power output significantly impact the cost of a sheet metal laser cutting machine. CO2 lasers, commonly used for cutting thicker materials, tend to be more affordable compared to fiber lasers, which excel in cutting thin sheets with high precision. Additionally, higher laser power translates to faster cutting speeds and increased productivity, but it also comes at a higher price point.

3. Automation and Features: Advanced features such as CNC control, automatic material feeding, and integrated CAD/CAM software enhance the functionality and efficiency of sheet metal laser cutting machines but also contribute to higher prices. Automation capabilities reduce labor costs and improve production throughput, making them worthwhile investments for businesses with high-volume production requirements.

Exploring Sheet Metal Laser Cutting Machine Prices

Now that we've identified key factors influencing sheet metal laser cutting machine prices, let's explore typical price ranges and considerations for businesses looking to invest in this technology.

1. Entry-Level Models: Entry-level sheet metal laser cutting machines, suitable for small businesses and hobbyists, typically start at around $20,000 to $50,000. These machines offer basic cutting capabilities for thin to medium-gauge sheets and may lack advanced features found in higher-end models.

2. Mid-Range Models: Mid-range sheet metal laser cutting machines, priced between $50,000 and $150,000, strike a balance between affordability and performance. They feature more robust construction, higher laser power, and additional automation options, making them suitable for a wide range of applications in medium-sized manufacturing facilities.

3. High-End Models: High-end sheet metal laser cutting machines, priced above $150,000, represent the pinnacle of cutting technology. These machines boast cutting-edge features, such as fiber laser sources, advanced automation, and precision machining capabilities, catering to the needs of large-scale production facilities and industries with stringent quality requirements.

Maximizing Value and ROI

While sheet metal laser cutting machine prices are an important consideration, businesses should also focus on maximizing value and return on investment (ROI) from their equipment purchases. Here are some strategies for achieving this:

1. Invest in Quality: While it may be tempting to opt for the lowest-priced machine, investing in a high-quality sheet metal laser cutting machine from a reputable manufacturer ensures reliability, performance, and long-term cost savings.

2. Consider Total Cost of Ownership: When evaluating machine prices, consider the total cost of ownership, including maintenance, energy consumption, and consumables such as laser optics and cutting nozzles. A slightly higher upfront investment may yield significant savings over the machine's lifespan.

3. Explore Financing Options: Many manufacturers offer financing options or lease-to-own programs that allow businesses to acquire cutting-edge equipment without a substantial upfront investment. Evaluate these options to determine the most cost-effective solution for your business.

4. Optimize Workflow Efficiency: Beyond equipment costs, focus on optimizing workflow efficiency to maximize productivity and ROI. Invest in training for operators, implement lean manufacturing practices, and continuously monitor and optimize processes to minimize downtime and maximize throughput.

Conclusion

Sheet metal laser cutting machines represent a transformative technology that offers unparalleled precision, efficiency, and cost-effectiveness in metal fabrication. While machine prices vary depending on factors such as size, capacity, and features, businesses can maximize value and ROI by investing in quality equipment, considering total cost of ownership, exploring financing options, and optimizing workflow efficiency. With the right investment strategy, sheet metal laser cutting machines can unlock new opportunities for growth and innovation in manufacturing.