Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

China precision cutting machine

In the competitive landscape of B2B industrial manufacturing, precision cutting machines are indispensable for businesses seeking to enhance their production capabilities. Originating from China, a hub for manufacturing and technological innovation, our precision cutting machines are crafted to meet the exacting standards of various industries. These machines are designed to deliver high-precision cuts, ensuring that every piece meets the stringent quality requirements of our clients. This detailed exposition will cover the key features, operational advantages, industrial applications, and after-sales support of our China precision cutting machines.

Key Features:

Advanced Cutting Technology: Our machines are equipped with state-of-the-art cutting technologies, including fiber lasers, waterjets, and plasma cutters, to handle a diverse range of materials with utmost precision.

CNC Control Systems: The integration of CNC (Computer Numerical Control) systems allows for intricate and repeatable cutting patterns, programmable for mass production or custom designs.

High-Quality Components: Sourced from reputable suppliers, the components used in our machines are of the highest quality, ensuring durability and consistent performance.

Rigid Machine Construction: The robust construction of our machines provides stability during operation, which is critical for achieving precise cuts and extending the machine’s lifespan.

Automation and Efficiency: Many of our precision cutting machines feature automated loading and unloading systems, reducing manual labor and enhancing overall efficiency.

Operational Advantages:

Enhanced Accuracy: Precision cutting machines from China are engineered to achieve tight tolerances, which is essential for high-precision parts and components.

Increased Productivity: With fast cutting speeds and reduced setup times, our machines enable higher throughput, allowing businesses to meet demanding production schedules.

Versatility: Capable of processing a wide array of materials, from metals to composites, our machines offer the versatility needed to tackle various cutting tasks.

Scalability: As businesses grow, our precision cutting machines can be scaled and integrated with additional modules to accommodate increased production needs.

Cost-Effective Operation: By optimizing material usage and reducing waste, our machines offer a cost-effective solution for industrial cutting requirements.

Industrial Applications:

Automotive Manufacturing: For producing precision-engineered components that are essential in the automotive industry.

Aerospace and Defense: Where the highest levels of precision are required for cutting components used in aircraft and military equipment.

Electronics: In the fabrication of intricate electronic components and PCBs (Printed Circuit Boards) where precision is paramount.

Metal Fabrication: Ideal for job shops and metal fabricators that require precise cutting for custom projects or mass production.

Medical Devices: Our machines meet the exacting standards necessary for the production of medical implants and surgical instruments.

After-Sales Support:

Comprehensive Training: We provide extensive training for machine operators to ensure they are proficient in using the equipment and maximizing its capabilities.

Maintenance Services: Our after-sales support includes scheduled maintenance to keep machines in optimal condition and prevent downtime.

Technical Assistance: A dedicated team of technical experts is available to assist with any operational challenges or troubleshooting needs.

Spare Parts Supply: We maintain a well-stocked inventory of spare parts to ensure quick replacements and repairs, minimizing any potential disruptions.

Customization and Upgrades: We offer customization options and upgrades to meet the evolving needs of our clients, ensuring their equipment remains at the forefront of cutting technology.

Conclusion:

Our China precision cutting machines are at the core of modern industrial manufacturing, providing B2B clients with the tools necessary to achieve high-quality, efficient, and precise cutting operations. By leveraging our advanced equipment and comprehensive support services, businesses can expect to see significant improvements in their production processes. Our commitment to excellence ensures that our clients receive not just a machine, but a complete cutting solution that drives their success.

Giá đỡ xoắn ốc chính xác

Giá đỡ xoắn ốc chính xác hoàn toàn được nhập khẩu, chứa tất cả các thành phần thép cần thiết và có điện trở hao mòn cao. Các thành phần quan trọng của giá sẽ không bị tổn hại bằng cách làm nguội laser. Sẽ không có bất kỳ vấn đề chất lượng nào ngay cả khi nó hoạt động liên tục ở tốc độ cao trong khi dưới sức mạnh mạnh và tải nặng.

Nguồn laser

Cụ thể, công suất cực đại cao, chiều rộng xung mở rộng và các tình huống công nghiệp xử lý lạnh, chẳng hạn như hàn điểm, hàn dây, khoan, cắt chính xác, v.v., được hưởng lợi từ công suất đầu ra cao hơn và công suất cực đại của tia laser sợi.

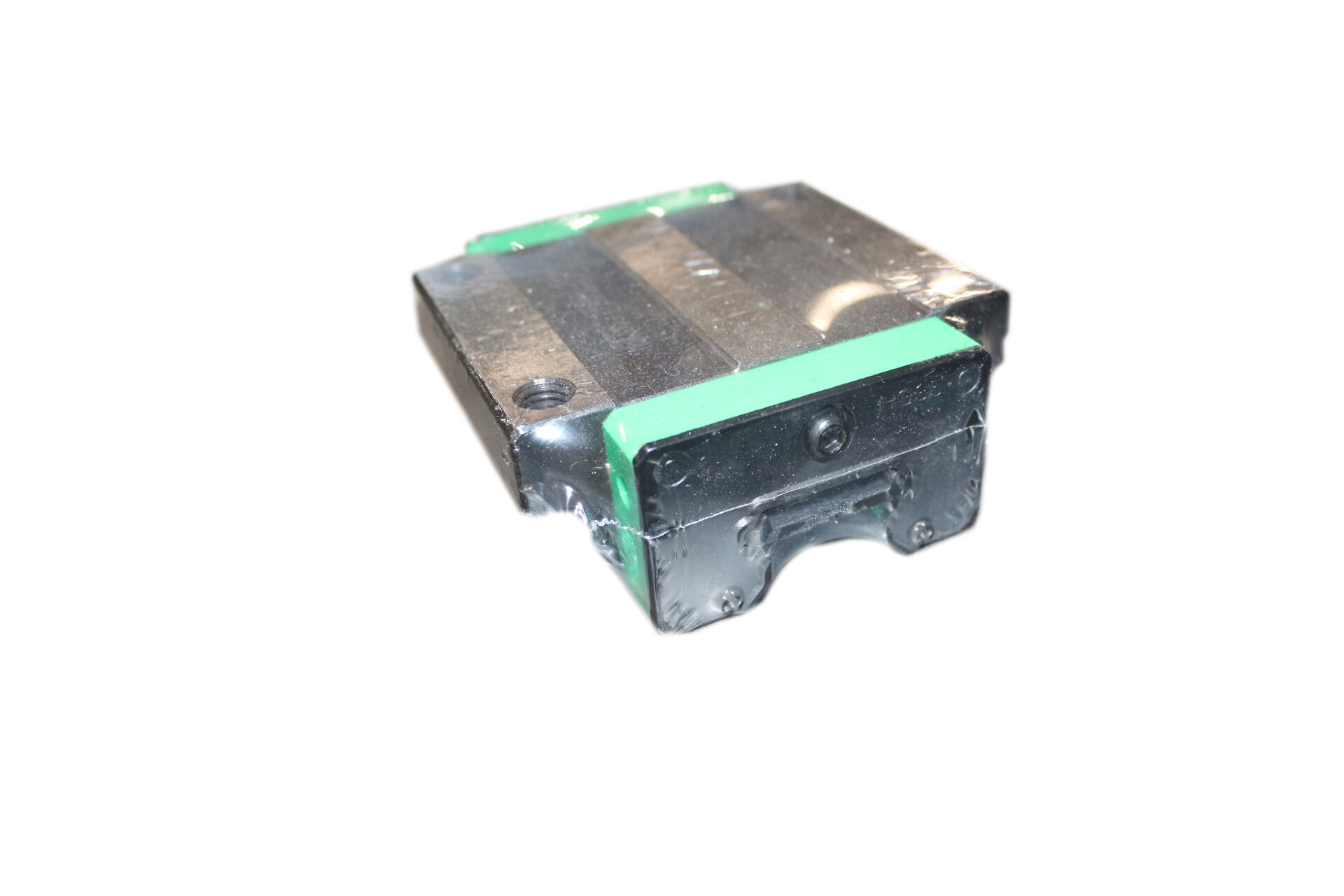

Đường sắt chính xác

Một loại phôi được gọi là đường ray chính xác làm cho thanh trượt di chuyển qua lại trên đường ray hướng dẫn bằng cách sử dụng các quả bóng hoặc con lăn. Nó có độ chính xác định vị cao và độ cứng cao và có hệ số ma sát là 1/40 đường ray cứng thông thường. Do đó, nó thường được sử dụng trong công cụ máy CNC, tự động hóa, máy móc chế biến gỗ CNC, máy cắt sợi quang, máy khoan, thiết bị điện tử 3C, máy mài cạnh kính, máy in quảng cáo, máy ảnh và các thiết bị công nghiệp khác.