Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

handheld fiber laser welding and cutting machine

The handheld fiber laser welding and cutting machine is a versatile and efficient tool that has revolutionized the metalworking industry. It offers precision and control in welding and cutting applications, making it an ideal choice for both small-scale and large-scale operations. Our company specializes in providing these machines at wholesale and custom options, ensuring affordability without compromising on quality. In this detailed overview, we will explore the features, benefits, applications, customization options, and support services associated with our handheld fiber laser welding and cutting machines.

Features:

Portability: The handheld design of our fiber laser machines allows for easy transportation and maneuverability, making it perfect for on-site jobs and flexible workshop layouts.

Advanced Fiber Laser Technology: Utilizing the latest in fiber laser technology, our machines provide high precision and clean cuts with minimal heat input, reducing the risk of material distortion.

User-Friendly Interface: Equipped with intuitive controls and a clear display, operators can easily adjust settings and monitor the welding or cutting process.

High Efficiency: With fast cutting speeds and low power consumption, our machines offer increased productivity and reduced operational costs.

Versatility: Capable of welding and cutting a wide range of materials including steel, aluminum, brass, and copper, our machines are suitable for various industrial applications.

Durability: Constructed with high-quality components, our handheld fiber laser machines are built to withstand the rigors of industrial use and provide long service life.

Benefits:

Enhanced Productivity: The speed and accuracy of fiber laser technology lead to faster completion of projects and a higher quality of work.

Reduced Waste: Precision cutting minimizes material waste, which is both cost-effective and environmentally friendly.

Lower Maintenance: Fiber lasers require less maintenance compared to traditional welding and cutting methods, saving time and money on upkeep.

Improved Safety: Handheld operation reduces operator fatigue and the enclosed beam delivery system enhances safety during use.

Flexibility: The ability to quickly switch between welding and cutting functions makes our machines highly adaptable to changing job requirements.

Applications:

Automotive Industry: For manufacturing and repair of vehicle parts.

Aerospace Sector: Precision fabrication of aircraft components.

Construction: Cutting and joining of structural steel elements.

Metal Fabrication: Custom shaping and assembly of metal products.

Art and Sculpture: Detailed work on metal art pieces.

Shipbuilding: Efficient welding and cutting of ship components.

Customization Options:

Power Output: We offer machines with various power outputs to match the needs of different materials and thicknesses.

Working Area: Customizable bed sizes to accommodate large or uniquely shaped workpieces.

Software Integration: Compatibility with specialized software for improved control and automation.

Additional Modules: Options for rotary attachments, wire feeders, and other accessories to expand machine capabilities.

Support Services:

Training: Comprehensive operator training to ensure safe and effective use of the machines.

Technical Support: Access to our team of experts for troubleshooting and advice.

Warranty: Our machines come with a warranty to provide peace of mind and protection for your investment.

After-Sales Service: We offer maintenance services and spare parts to keep your machine in optimal condition.

Conclusion:

Our handheld fiber laser welding and cutting machines represent a fusion of portability, performance, and precision. With customizable options and dedicated support, we cater to a diverse range of industries and applications. By choosing our machines, you are investing in a tool that will not only enhance your operational efficiency but also provide a quick return on investment through its durability and low running costs.

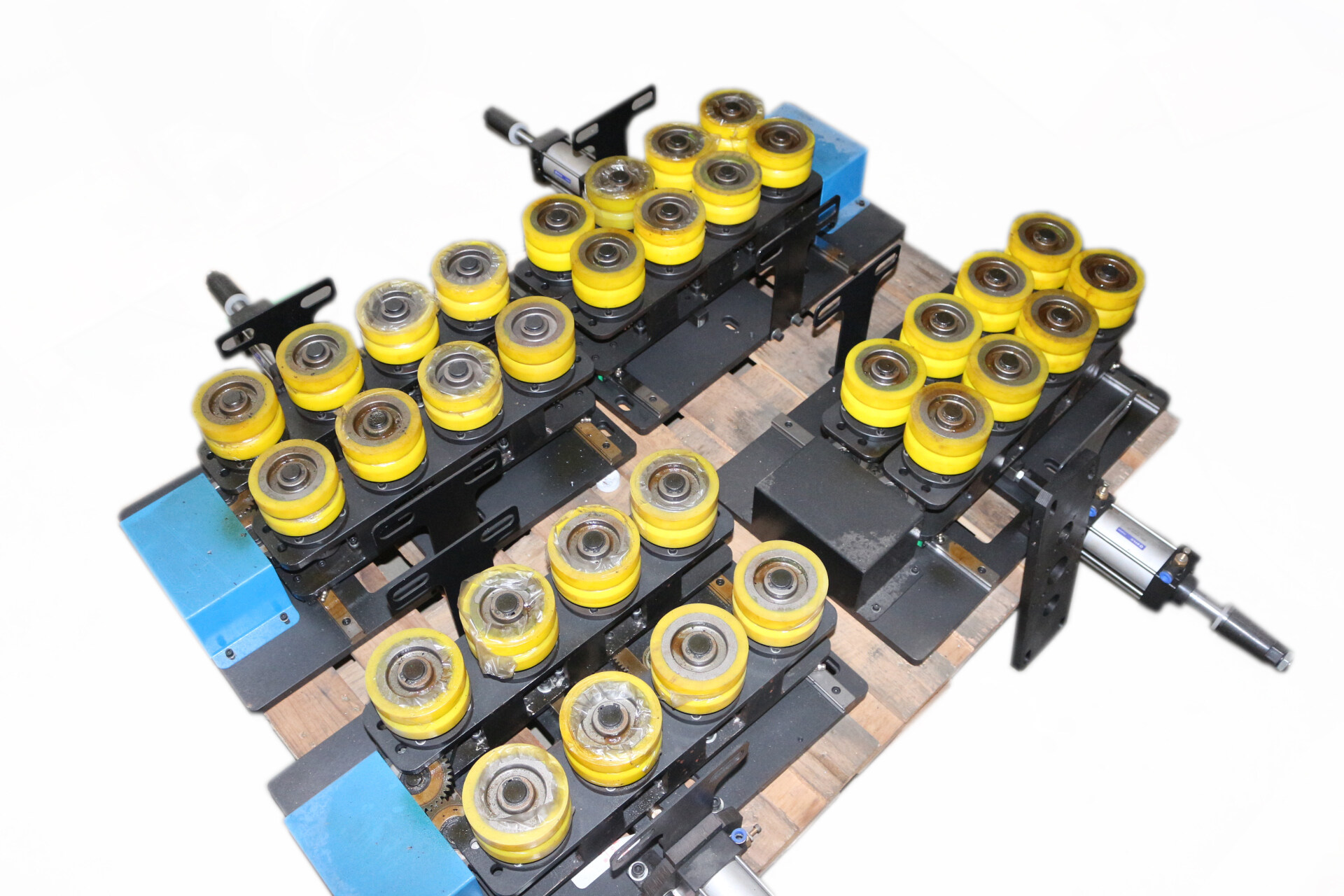

Tập trung bánh xe cho ăn

Bánh xe cho ăn của chúng tôi cực kỳ chống mài mòn, thức ăn đều đặn và cắn chặt. Để ngăn chặn vết cắn lỏng lẻo và bảo tồn chất lượng in được cải thiện, bạn nên thay thế cái ban đầu sau một thời gian sử dụng.