Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

industrial fiber laser source module

The industrial landscape is witnessing a transformative shift with the advent of cutting-edge technologies. Among these innovations, the industrial fiber laser source module stands tall as a cornerstone in enhancing manufacturing precision, efficiency, and reliability.

Unraveling the Technology:

The industrial fiber laser source module represents a pinnacle in laser technology, harnessing the power of optical fibers to deliver superior performance. Its compact design belies its immense capability, offering unparalleled precision in various industrial applications.

Precision Redefined:

At the core of this module lies precision. Its ability to generate high-intensity laser beams with exceptional accuracy enables precise material processing, cutting, and engraving across a spectrum of materials with finesse and minimal wastage.

Efficiency Amplified:

Manufacturing processes benefit immensely from the efficiency this module brings. Its rapid and controlled energy delivery optimizes production timelines, reducing downtime and increasing output without compromising quality.

Reliability Personified:

The reliability of the industrial fiber laser source module stands as a testament to its robust design. Its resilience to harsh working environments and consistent performance over prolonged operational periods ensures uninterrupted workflow and consistent results.

Introducing JINGWEN:

In this realm of cutting-edge technology, JINGWEN emerges as a pioneering brand, setting new standards of excellence. Known for its commitment to innovation and quality, JINGWEN's industrial fiber laser source modules epitomize reliability, precision, and durability, empowering industries to achieve unparalleled manufacturing capabilities.

In conclusion, the industrial fiber laser source module epitomizes the fusion of innovation and efficiency in modern manufacturing. With JINGWEN leading the charge, this technology heralds a new era of precision and productivity, redefining the benchmarks of industrial excellence.

Nguồn laser

Cụ thể, công suất cực đại cao, chiều rộng xung mở rộng và các tình huống công nghiệp xử lý lạnh, chẳng hạn như hàn điểm, hàn dây, khoan, cắt chính xác, v.v., được hưởng lợi từ công suất đầu ra cao hơn và công suất cực đại của tia laser sợi.

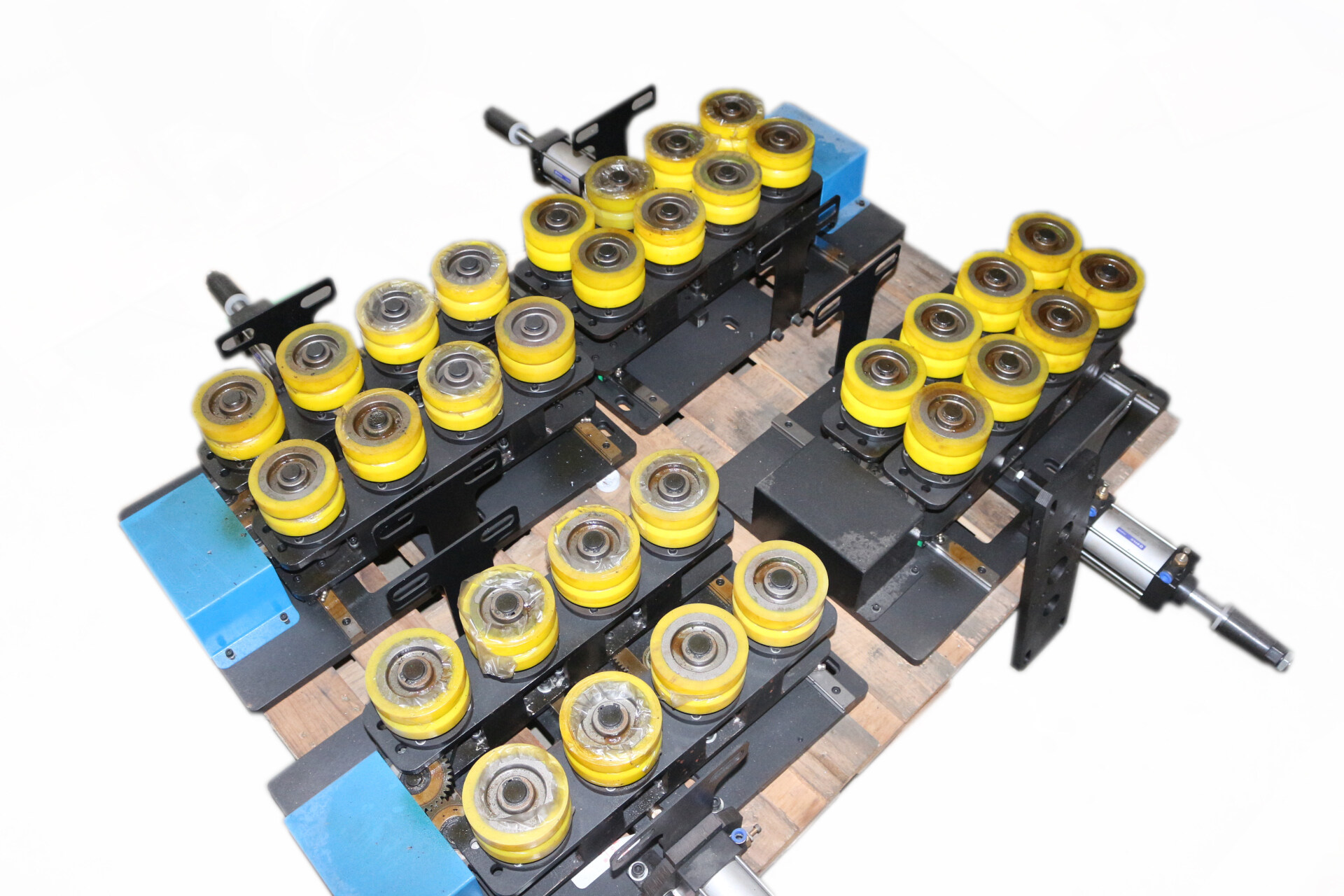

Tập trung bánh xe cho ăn

Bánh xe cho ăn của chúng tôi cực kỳ chống mài mòn, thức ăn đều đặn và cắn chặt. Để ngăn chặn vết cắn lỏng lẻo và bảo tồn chất lượng in được cải thiện, bạn nên thay thế cái ban đầu sau một thời gian sử dụng.