Lỗi định dạng email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

laser source for precision cutting

In the realm of modern manufacturing, precision cutting has become a cornerstone of efficiency and quality. At the heart of this technological advancement lies the indispensable component - the laser source. It’s a catalyst transforming industries by enabling unparalleled accuracy, speed, and versatility in material processing.

Unveiling the Power of Laser Sources:

Laser sources are the driving force behind the precision cutting revolution. These sources emit concentrated beams of light, offering exceptional precision that conventional methods often struggle to match. By harnessing the principles of photonics, these sources enable manufacturers to intricately slice through a myriad of materials, ranging from metals to composites, with supreme accuracy.

Versatility in Applications:

The beauty of laser sources resides in their adaptability across diverse industries. From automotive to aerospace, and from electronics to medical devices, the applications are limitless. Whether it's shaping intricate components or cutting complex patterns, laser sources empower manufacturers to achieve unparalleled levels of precision and intricacy, optimizing the production process with minimal material waste.

Driving Efficiency and Innovation:

The integration of laser sources into manufacturing processes has redefined efficiency standards. These sources operate at remarkable speeds, significantly reducing production times and enhancing throughput. Moreover, their precision facilitates the creation of intricate designs that were once deemed unattainable, fostering innovation across industries.

JINGWEN: Pioneering Excellence in Laser Technology

Amidst the myriad of options available, JINGWEN stands out as a trailblazer in the realm of laser technology. With a commitment to innovation and quality, JINGWEN's laser sources epitomize reliability, precision, and performance. Backed by cutting-edge research and development, JINGWEN's products redefine the benchmarks of excellence, empowering businesses to elevate their manufacturing capabilities.

In conclusion, the utilization of laser sources for precision cutting is more than just a technological advancement; it's a catalyst for progress. As industries continue to evolve, JINGWEN remains at the forefront, providing the tools that shape the future of manufacturing.

Giá đỡ xoắn ốc chính xác

Giá đỡ xoắn ốc chính xác hoàn toàn được nhập khẩu, chứa tất cả các thành phần thép cần thiết và có điện trở hao mòn cao. Các thành phần quan trọng của giá sẽ không bị tổn hại bằng cách làm nguội laser. Sẽ không có bất kỳ vấn đề chất lượng nào ngay cả khi nó hoạt động liên tục ở tốc độ cao trong khi dưới sức mạnh mạnh và tải nặng.

Nguồn laser

Cụ thể, công suất cực đại cao, chiều rộng xung mở rộng và các tình huống công nghiệp xử lý lạnh, chẳng hạn như hàn điểm, hàn dây, khoan, cắt chính xác, v.v., được hưởng lợi từ công suất đầu ra cao hơn và công suất cực đại của tia laser sợi.

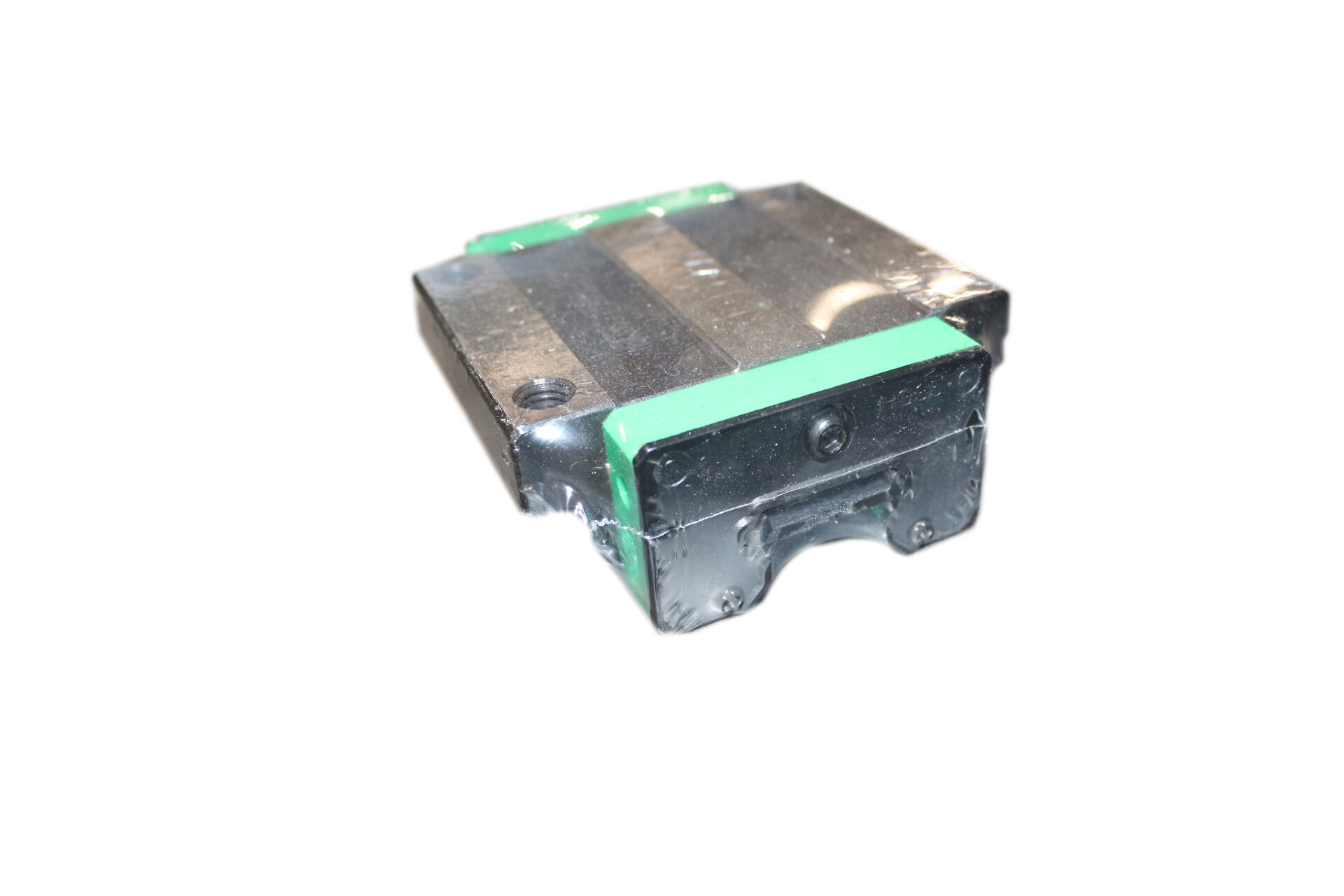

Đường sắt chính xác

Một loại phôi được gọi là đường ray chính xác làm cho thanh trượt di chuyển qua lại trên đường ray hướng dẫn bằng cách sử dụng các quả bóng hoặc con lăn. Nó có độ chính xác định vị cao và độ cứng cao và có hệ số ma sát là 1/40 đường ray cứng thông thường. Do đó, nó thường được sử dụng trong công cụ máy CNC, tự động hóa, máy móc chế biến gỗ CNC, máy cắt sợi quang, máy khoan, thiết bị điện tử 3C, máy mài cạnh kính, máy in quảng cáo, máy ảnh và các thiết bị công nghiệp khác.